| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: BRJ-1600

Additional Info

Packaging: Seaworthy packing

Productivity: 20sets/month

Brand: YBBA

Transportation: Ocean

Place of Origin: Shandong, China

Supply Ability: 200SETS/Year

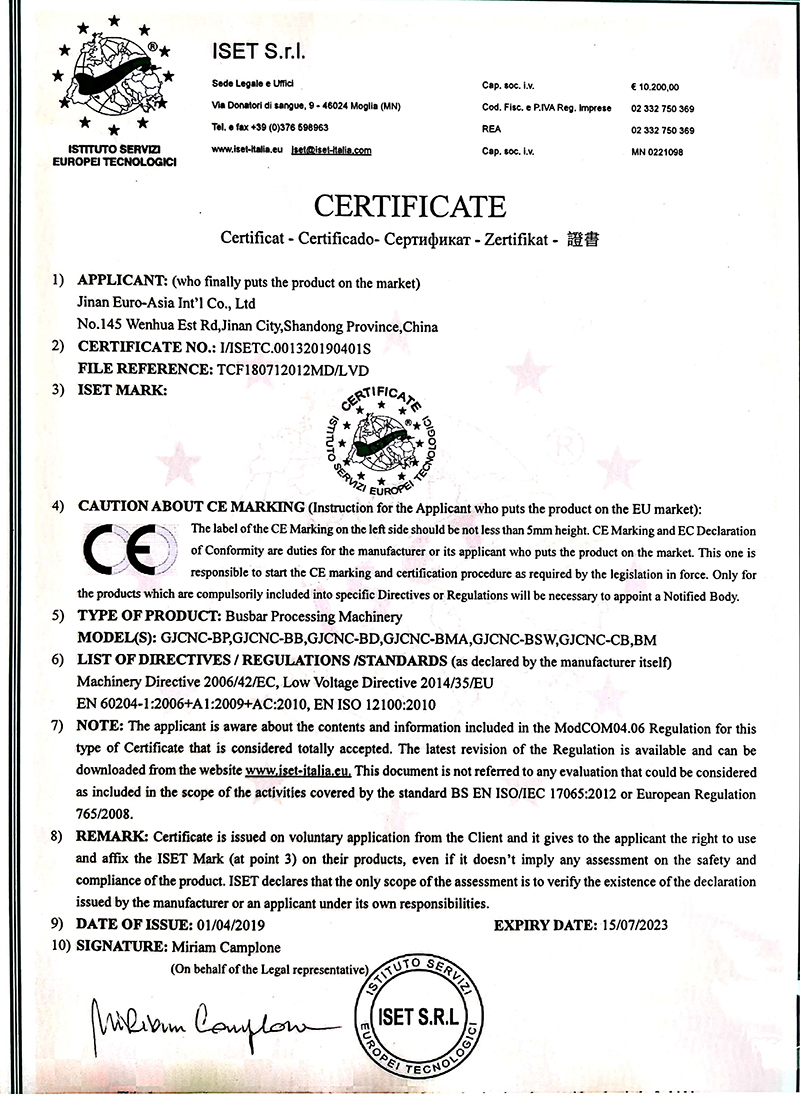

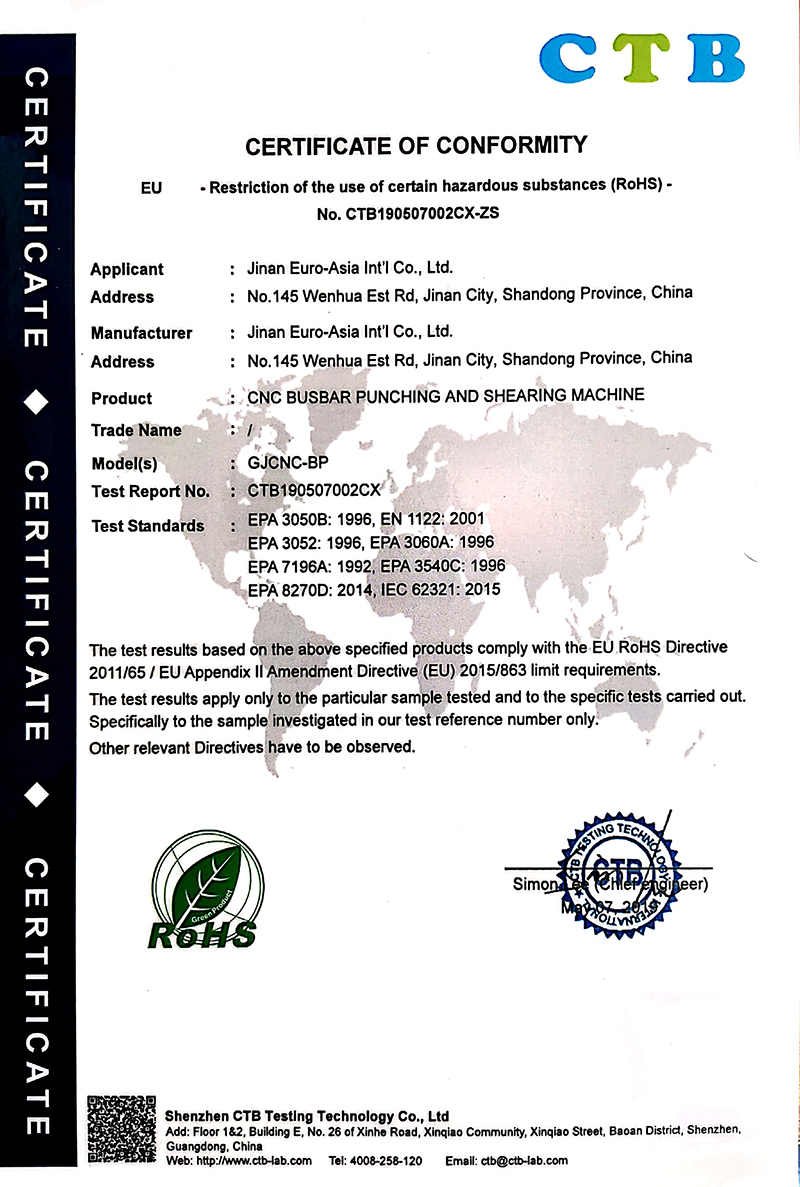

Certificate: ISO

Port: Qingdao

Product Description

Application

1, Instruction

Foil winding machine is suitable for transformer and other electric industry foil winding.

Foil coil take different thickness copper belt or aluminum belt as

conductor, take wide belt type insulation material as layer insulation,

take narrow belt type insulation material as end insulation, finish foil

winding in foil winding machine once time and form a roll status

coil.at the same time, the lead wire in outside of coil weld and surface

package are finished. All kinds of function of this equipment supply

enough support for foil winding in making suitable coil. This machine is

necessary equipment for this electric product.

2. Technical parameters:

Model

Paramet

BRJ-600

BRJ-800

BRJ-1100

BRJ-1400

BRJ-1600

Foil width of coil (mm)

≤600

≤800

≤1100

≤1400

≤1600

Outer diameter of the coil (mm)

120-600(700)

120-600(850)

150-800(1000)

150-900(1300)

200-1100(1500)

Foil thickness (mm)

0.3-2.5single and double layers

Winding speed

0-30r/min

0-30r/min

0-20r/min/0-30r/min

0-20r/min

0-17r/min

Max tension of foil (single layer)

≤6KN

≤8KN

≤10KN

≤13KN

≤15KN

Automatic welding model

DC Pulse Argon arc welding/cold pressure welding

Deflection adjusting accuracy of foil

≤±0.5mm

≤±0.5mm

≤±0.5mm

≤±0.5mm

≤±0.5mm

Max Tension of interlayer insulation

≤0.2KN

≤0.2KN

≤0.4KN

≤0.4KN

≤0.4KN

Installation capacity

15KW/25KW

20KW/30KW

25KW/35KW

40KW

45KW

3.Composition

Decoiler for foil coil

foil edge burr removing and dust clean device

Foil coil error correcting device

Foil Feeding mechanism

Electrical Tension device

Foil Sheet cutting device

Decoiler for layer insulation

Layer insulation edge cutting mechanism

End insulation strip installation device

Winding device

Welding device(TIG welder)

PLC Control System

Packing details

1) Applying Anti-Rust Oil

2) Covering with stretch film

3) Covering aluminum air bag

4) Vacuuming air bags

5) Boxing all the pallet

6) Loading to the container

Our service

--- Inquiry will be replied within 2 hours.

--- All the way tracking service offered from placing order to delivery.

--- We can provide professional guide installation.

--- One year warranty and all round after sale service.

--- Customized design and flow chart are available for our clients.

--- Independent R&D team and strict & scientific management system.

CONTACT US

JINAN EURO-ASIA INT'L CO., LTD

Contact Person: James

Phone:86-0531-81670640

Fax:

Address: Rm211,No.145 Wenhua Est Rd, Jinan City, Shandong Province, China,Jinan,Shandong